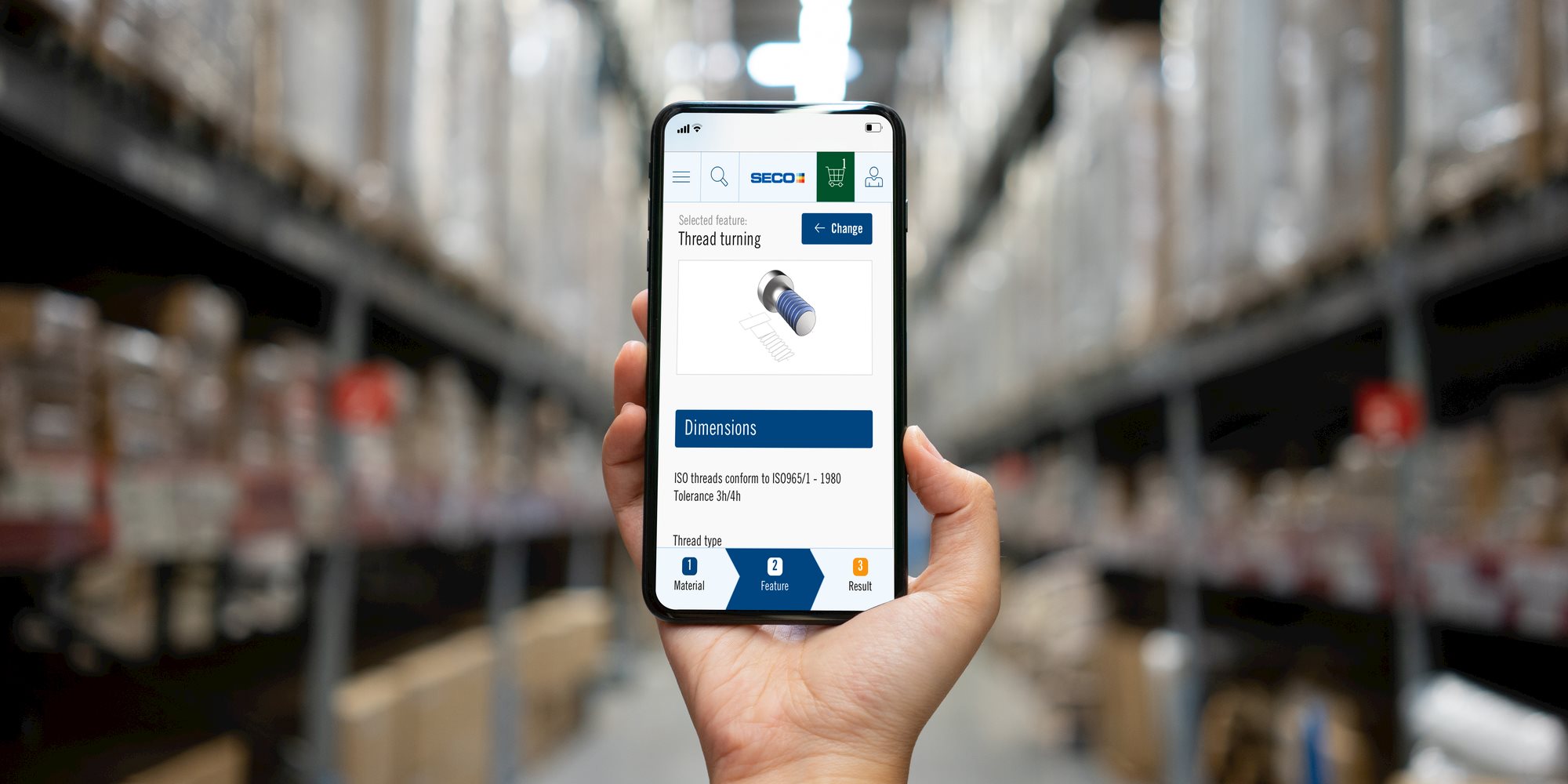

SAVE TIME AND GET TOOL ADVICE YOU NEED NOW WITH SECO SUGGEST

Let Seco Suggest provide you with instant, reliable and expert machining advice that is best suited for your applications.For today’s machine shops, jobs are increasingly more complex, skilled operators are harder to find, tolerances are tighter and delivery times are shorter. To keep up, you need technical competence, and you need it now. Let Seco Suggest provide you with instant, reliable and expert machining advice that is best suited for your applications. A free online resource on secotools.com, Suggest uses key information about your application to quickly and easily identify productive, cost-effective tools and cutting strategies – and delivers an ideal tooling solution, as well as a full list of alternatives, in less than a minute.

Want to know more about how Suggest is working?

Click here to start using Suggest

Today’s machine shops are always on the run. Jobs are increasingly more complex, tolerances are tighter and delivery times are shorter. You must continuously find ways to reduce machining time to maintain your competitiveness and to meet growing customer demands. Unfortunately, you have no time to test, optimize and determine the best solution for every application. To make matters worse, skilled labor is hard to find, and your experienced staff is overwhelmed. You need technical competence, and you need it now.

Let Seco Suggest provide you with instant, reliable and expert machining advice that is best suited for your applications.

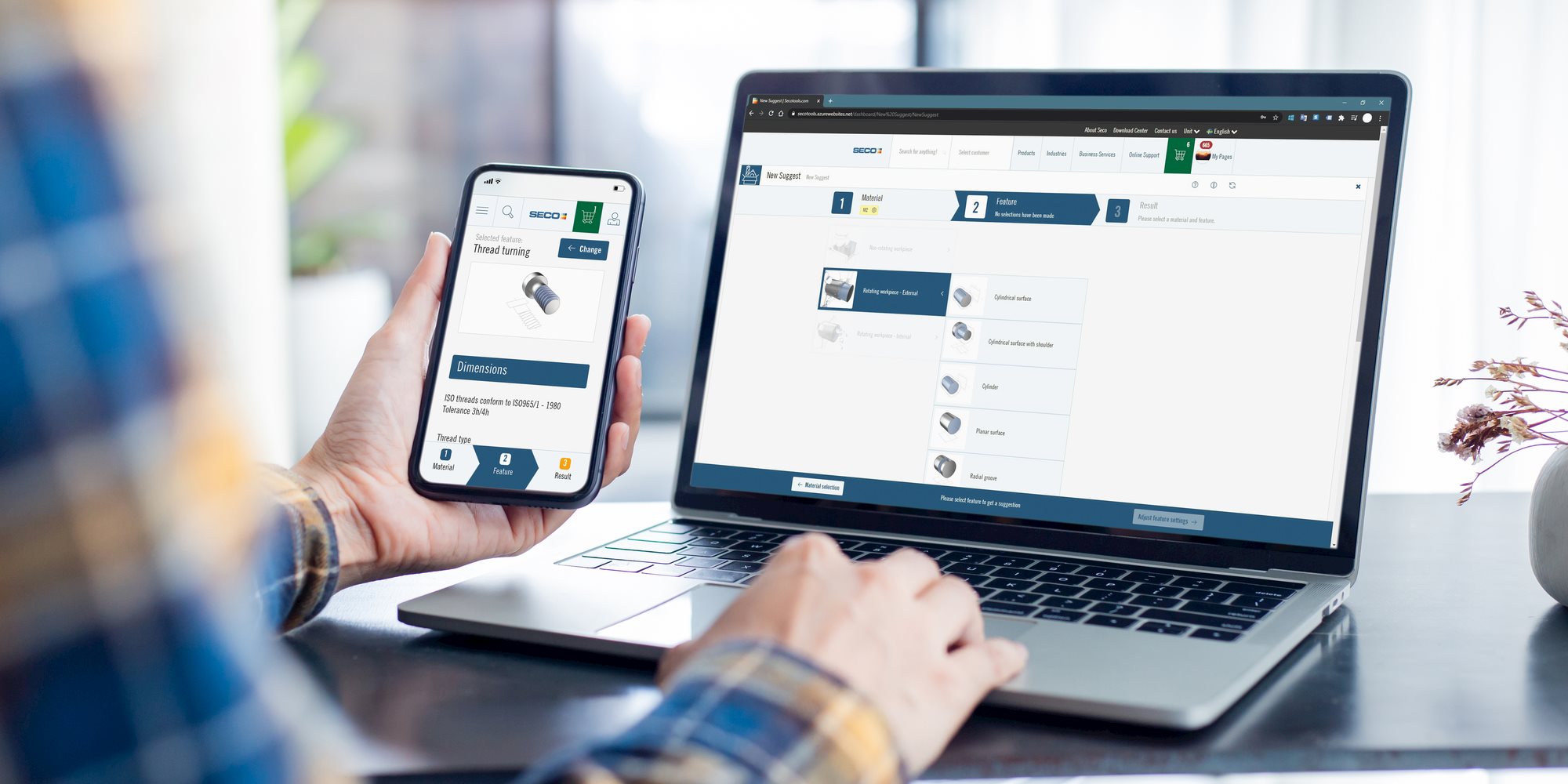

With a wide-ranging catalog that covers the entire metal-cutting industry and a newly streamlined design for the greatest ease of use, Suggest is a free online resource on secotools.com that helps you quickly and easily identify productive, cost-effective tools and cutting strategies for your individual applications. Simply enter the information about your workpiece material and part feature and Suggest draws on decades of Seco Tools expertise in less than a minute to find your ideal tool and the cutting data that will help you achieve the highest productivity.

Your challenge: No time to determine the optimal tool and cutting parameters for your application.

The Seco solution: Quickly and easily access the tools and cutting data best fitted for your needs with Suggest.

There are multiple ways to achieve your specific machining goals. That is why Suggest offers a complete list of alternative products in addition to initial recommendations that may meet your unique application needs better than the initial recommendation. And with product specifications and availability information, all updated in real time, you can easily find those solutions that will get your process underway and optimized as quickly as possible.

Your challenge: Today’s highly complex parts are pushing your machining expertise to the limit.

The Seco solution: Leverage the expertise of Seco Tools any time with automated technical assistance that can provide recommendations in seconds.

Now, in addition to helping users find the perfect tool for their unique application, Suggest can provide fully optimized CNC codes with special functionality adapted for Seco threading tools and inserts. After providing application details, Suggest will automatically provide CNC code optimized for the selected tool so you’ll be ready to thread parts as soon as your solution arrives.

With the new Suggest material search function, you can easily find your material among a comprehensive list, and link it to a Seco Material Group. As we know that each material could be different, we now give you the possibility to customize the material calibration.

Once you found the perfect fit, you can simply save this specific material in your material library, and access it later on in one click for another usage.

Get the most efficient cutting data for your specific application and material is hard to find. Suggest provides you the best tool combination in regards to your needs, and also all the cutting data to machine your workpiece.

In addition, you will find several alternative recommendations. Suggest allows you to compare these solutions, the products and the cutting parameters. If you want to change some cutting parameters like feed, speed or number of passes, you can easily adjust them and recalculate the outputs.

Thanks to your Seco account, you can access to advanced cutting data such as cutting time, average chip thickness or machine power consuption.

Your challenge: Trying to optimize new machining operations with old tooling technology.

The Seco solution: Access clear, reliable and up-to-date tooling recommendations for your applications.

Click here to start using Suggest

Related content

SUGGEST

GET YOUR SECO ACCOUNT

HOW TO GET YOUR CNC CODE ONLINE - CLOSEDOWN OF THREADING WIZARD

My Pages Portlet View / Seco Applications

Explore the New Seco Website

Online Support

Product Range Update Application

Video: Dynamic milling now supported in Seco Suggest

Register on Secotools.com

Seco Online Store

Suggest: your technical advisor

SECO JSE510 SOLID END MILL SERIES

Seco News

Access to Suggest

Seco Assistant

Video: Apply for an Account - Secotools.com Tips & Tutorials

Get your Seco account

Threading Wizard

Online Catalogs

Electronic Data Interchange (EDI)

EDI

JETI CONVERSION GROOVING & PARTING-OFF CAPTO

SECO TOOL IDENTIFICATION

ISO K THREADING TAPS

MUTUAL GAINS FOR ACADEMIA AND INDUSTRY

Recycling

HIGH FEED SQUARE CUT SIZE 14 INSERT

ISO K THREADING TAPS

SECO ASSISTANT - GET THE NEW SECO MOBILE APP

HIGH FEED SQUARE CUT SIZE 14 INSERT

THREE IS THE MAGIC NUMBER - JOINT APPROACH HAS DAWNLOUGH FLYING HIGH

THE LIGHTER SIDE OF HEAVY TRANSPORT

A SKY-HIGH PARTNERSHIP

New MEP process takes hole deburring to new depths

CLEANER STEEL CUTS THE CHAIN

Hotspot Slovenia

MANUFACTURING TRANSFORMATION

Interactive catalogs of Seco News

JETI CONVERSION GROOVING & PARTING OFF CAPTO

FEEDMAX -MS DRILL

JABRO® CERAMICS

TP25 GRADE

Contact us

Zero Waste - For a Low Carbon Future

THREADMASTER™ ISO-S THREADING TAPS

DURATOMIC® TM1501, TM2501, AND TM3501 GRADES

DOUBLE TURBO 16

MODULAR QC (QUICK-CHANGE) TOOLHOLDER FOR SMALL PART MACHINING

JC898 AND JC899

NEW MP MILLING GRADES

SECO-CAPTO TOOLHOLDERS & CASSETTES FOR ADVANCED MATERIAL

JETI ISO TOOLHOLDER RANGE EXTENSION

FUNDING GREEN AMBITIONS

NEW JC898 AND JC899 PREVENT DELAMINATION IN HYBRID STACKED MATERIAL MACHINING

GEARING UP FOR THE WIN

MEET THE MINI MILLS

SECO TOOLS ANNOUNCES RELEASE OF NEW DURATOMIC® TM GRADES FOR STAINLESS STEEL TURNING

NEW SECO THREADING GRADE EXCELS IN CRITICAL PART APPLICATIONS

CUSTOMER SATISFACTION DEPENDS ON RELIABLE MACHINING PROCESSES

THE FUTURE IS ELECTRIC

NEW 335.19 AND 335.18 DISC MILL CUTTERS

SECOMAX™ CW100 INSERT GRADE

SECO ROUND 10 AND 16 COPY MILLING INSERTS

XP08 ALUMINIUM ROUTER

RANGE EXTENSION OF SHELL MILL HOLDERS, SMALL FACE & SIDE LOCK HOLDERS IMPROVEMENTS

COMBIMASTER™ M20

EASYSHRINK EVO

UNIVERSAL DRILLS 8XD AND 12XD

NEW SECO GL THREADING HEAD ADDITIONS EXPAND RANGE OF DEEP-HOLE SOLUTIONS

NEW SECO NIAGARA CUTTER™ 5-FLUTE END MILL DELIVERS EXTREME VERSATILITY

A GOOD DAY FOR A WORLD RECORD

PARTNERSHIP BEYOND TOOLING

THE MACHINIING FLUID MAGICAN

R220.88 WITH SNMU INSERTS

TTP2050

JM500 MICRO END MILLS

JETI CONVERSION GROOVING AND PARTING-OFF

DOUBLE QUATTROMILL™ 14

JM100 MINI END MILLS

LP09 INSERTS

DOUBLE OCTOMILL™

RCMX RANGE

UNJ AND MJ THREADING INSERTS

POWER MILLING CHUCKS

JS750 END MILLS

PCBN INSERTS

STEADYLINE® & ø25MM (1”) SERIES

STEADYLINE® TURNING BAR ADDITIONS

JETSTREAM TOOLING®

DOUBLE QUATTROMILL™ 22

Controlling mechanical loads in milling operations